Introduction

How to load Thermal Transfer Labels and Ribbons in your Global Shop industrial printer.

-

-

Direct transfer labels will show a grey mark if you scrape your thumbnail along it, while thermal transfer will not. Make sure the labels you are using are of the Thermal Transfer variety.

-

In the first picture, the Direct Transfer labels (with the grey mark) are on the right. You want the Thermal Transfer labels on the left, which won't show a dark mark if scratched with your thumbnail.

-

Lift the cover all the way open, until it's resting on the top of the printer.

-

-

-

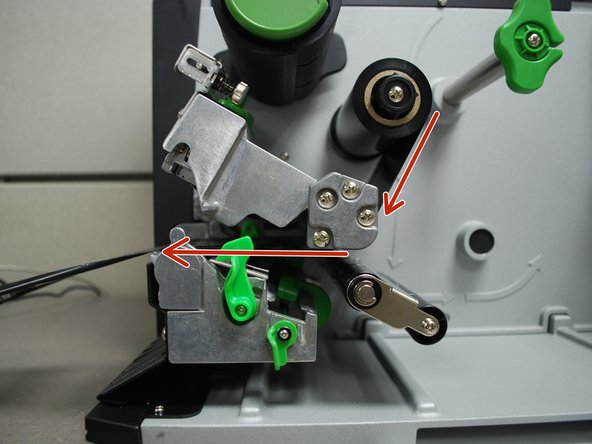

With one hand, press down on the top of the printhead.

-

With the other, push the green release lever to the right.

-

The printhead can now be lifted up.

-

-

-

Place the roll of ribbon on the ribbon spindle - the black plastic spindle located a little bit above and behind the print head.

-

Feed the ribbon under the printhead and out to the front, making sure to feed it through the ribbon sensor (the black clip on the bottom of the printhead).

-

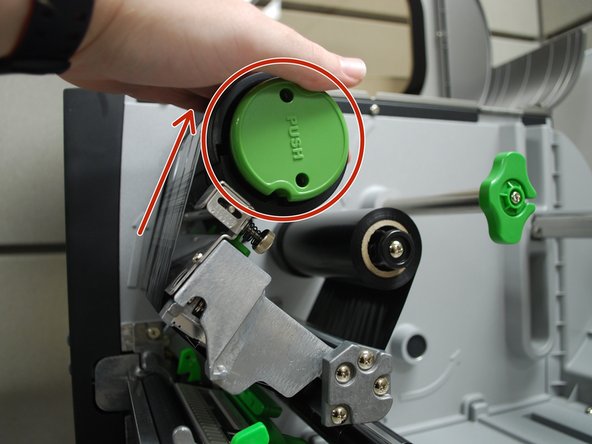

Tightly wind the ribbon around the ribbon rewind spindle until taut - it has a black plastic surface and a green cap that says "PUSH."

-

Make sure the ribbon is properly spread out and flattened.

-

-

-

Test the orientation of the ribbon:

-

Get a piece of regular tape.

-

Put the piece of tape on the ribbon.

-

Remove the piece of tape.

-

If there is ink on the tape and ink came off the ribbon, the ribbon is facing the correct direction. If there is no ink, repeat Step 4 with the ribbon facing the correct direction.

-

-

-

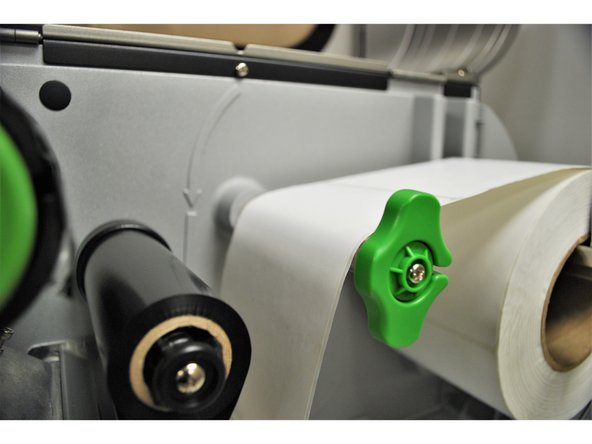

Place the roll of labels on the spindle, so that they unroll from the top.

-

Fold the label roll guard back up and and press it against the side of the roll.

-

-

-

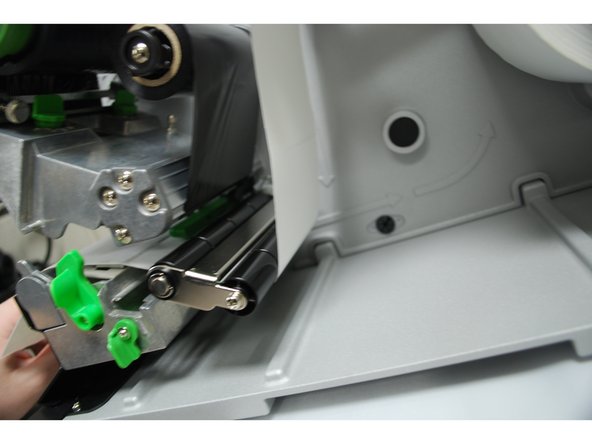

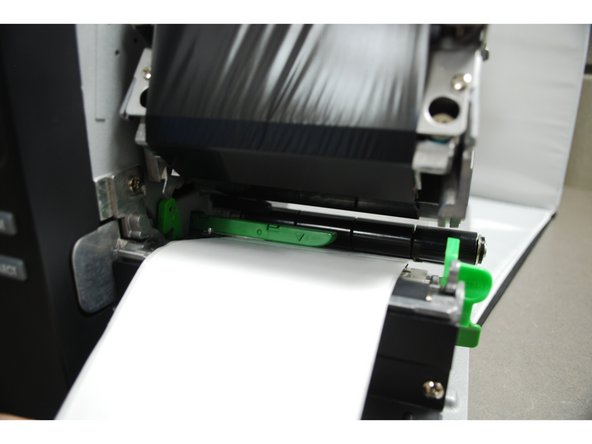

Feed the labels over the media guide bar, and under the damper roller.

-

Feed the labels through/under the green media sensor bar.

-

Pull through until the leading edge of on label is even with the platen.

-

-

-

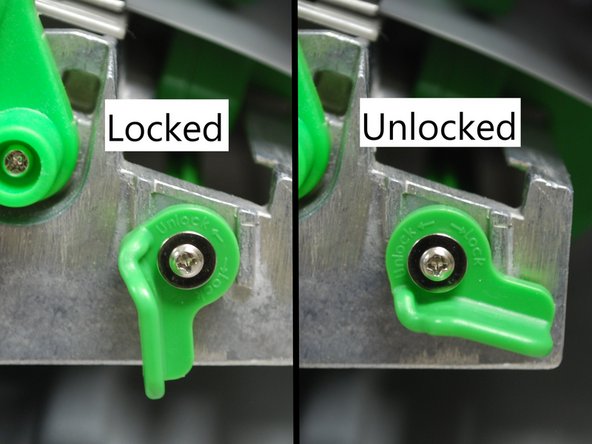

Unlock the media sensor locking lever by twisting it counter-clockwise.

-

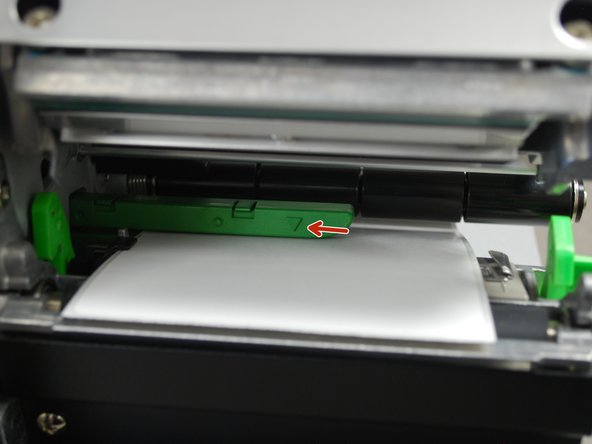

After unlocking the lever, use the green tab (second picture) underneath the damper roller to adjust the media sensor.

-

The arrow on the media sensor (3rd picture) should be approximately centered on the label. The arrow marking indicates the position of the sensor the printer uses to calibrates, so it's important to make sure it's in the right place.

-

Once the media sensor has been adjusted, switch the locking lever back to the "locked" position by twisting it clockwise.

-

-

-

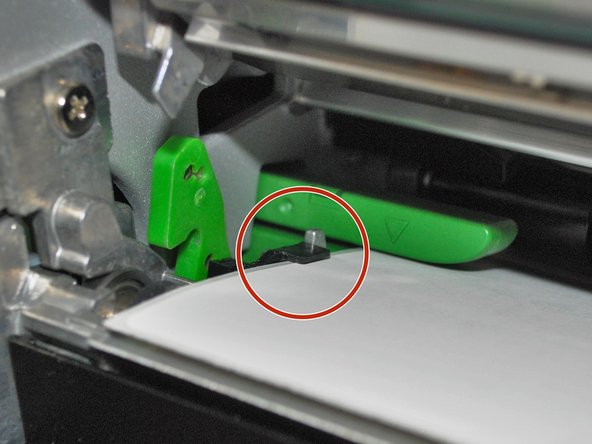

Make sure the far edge of the label roll lines up with the black clip at the back of the printer.

-

Slide the metallic clip next to the release lastch until it fits against the close edge of the labels.

-

These clips keep the labels running straight, so it's important to make sure they're not so tight they pinch the labels or otherwise stop them from moving.

-

-

-

Close the printhead by pressing down firmly on top until you hear a 'click,' making sure that the green release lever is latched closed.

-

Close the cover on the printer.

-

-

-

Press the "Feed" button, to make sure the labels line up with the tear-off edge when they eject.

-

If they don't, open the printer, release and lift the printhead, and pull the labels forward until hey line up.

-

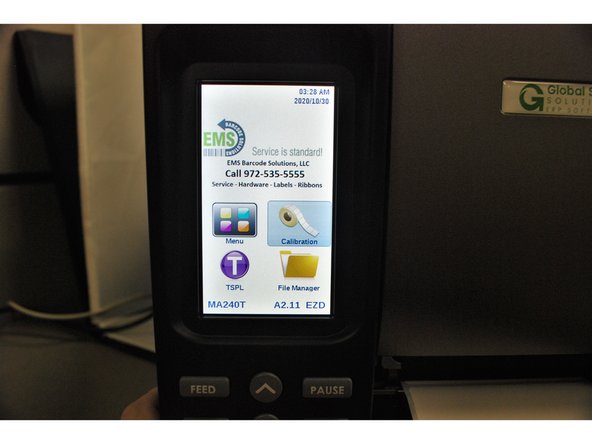

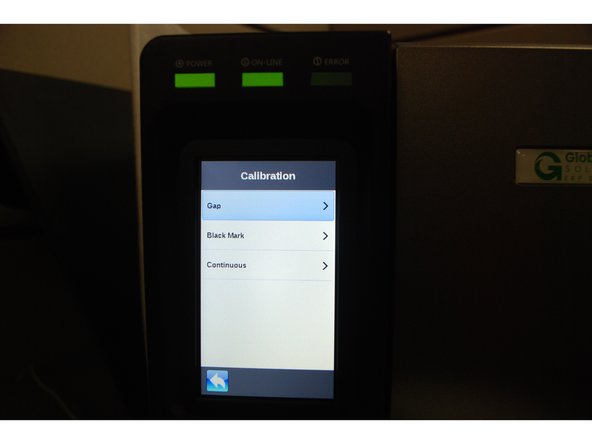

On the printer screen, select "Calibrate," and then "GAP."

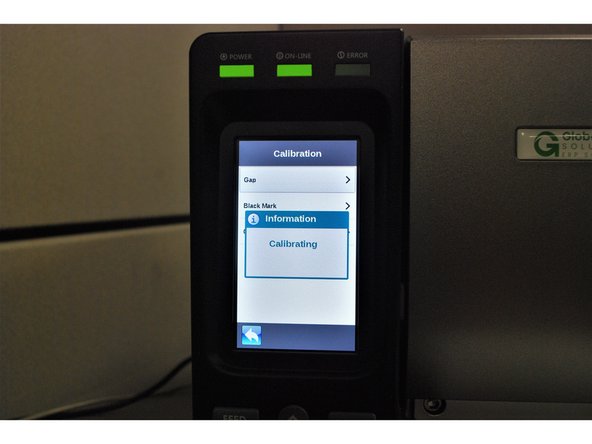

-

The printer will now self-calibrate; several blank labels will be printed in the process.

-